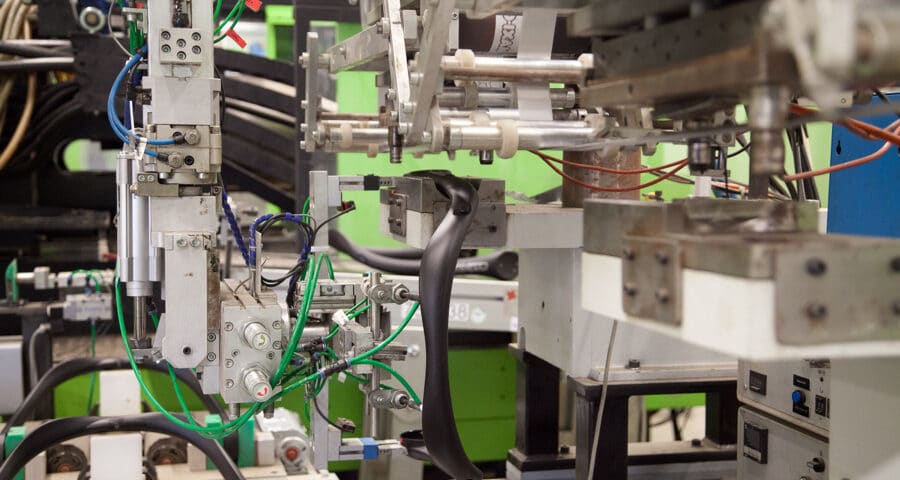

Compact injection moulding is a very suitable technique for products with a smaller wall thickness. DPI injection moulds plastic products seamlessly with dimensions up to 2 meters.

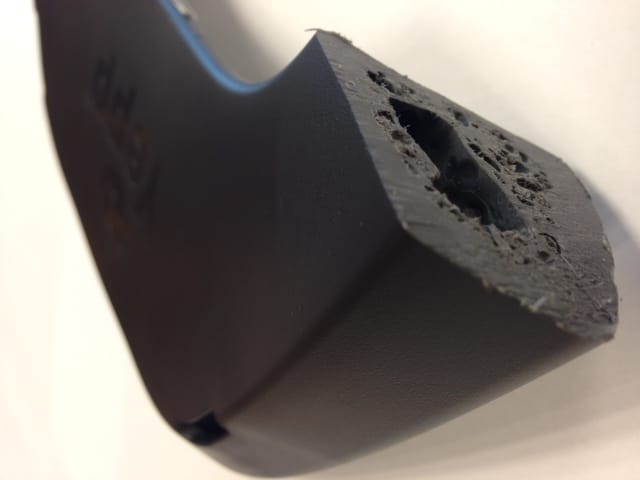

Gas injection is a technique that allows DPI to manufacture hollow or partially hollow plastic products.

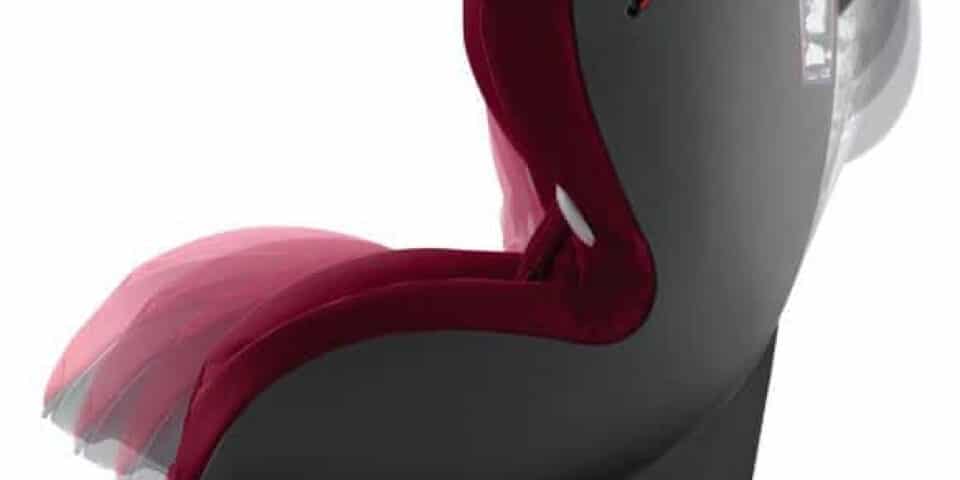

Great design flexibility and significant cost savings: that is the benefit of our component technology.

The automation of the manufacturing process resulted in a new and unique process called: in-line labelling.

By giving products a surface treatment, DPI can provide various decorations, coatings and varnishing to end-products.